- McConnel & Kennedy mills

-

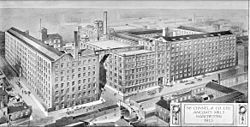

McConnel and Kennedy Mills

Location Ancoats [1][2] McConnel & Kennedy Mills are a group of cotton mills on Redhill Street in Ancoats, Manchester, England. With the adjoining Murrays' Mills, they form a nationally important group.

Contents

The Mills

- Old Mill 1797

- Long Mill 1801

- Sedgewick Mill, 1818–1820

- Sedgewick New Mill 1912

- Royal Mill (New Old Mill 1912) renamed 1942

- Paragon Mill 1912, 8 storeys. World's tallest cast iron structure when built.

History

The first phase of mills in Manchester were water-powered, taking their power from the River Medlock (such as Garratt Mill (1760), Holt's Mills, Meredith's Factory (1760, Gaythorn Mill (1788), Wood Mill (1788), Knott Mill (1792)[3] and then the Shooters Brook. Salvin's ran a room and power mill (1780) on the Shooters Brook in Ancoats, and it was here that the partnership of Sandford, McConnel and Kennedy took room. Salvin's Factory failed to get enough power from Shooters Brook, so improved the head of water with a Savery type steam-powered pump. In 1793 John Kennedy directly connected a spinning mule to a steam engine. On 2 March the partnership was terminated and 1795, McConnel and Kennedy moved out, to other premises in Derby Street. Kennedy was still manufacturing and selling spinning mules until 1801.[4] The next phase of mills were powered by Boulton and Watt double-acting beam engines. Though flowing water was no longer required—a considerable amount of water was needed for the engines condensor—but that could easily be provided by a mill lodge, a canal or a brook. The first Boulton and Watt engine in Manchester had been bought by Drinkwater's Mill, Piccadilly in 1789, and installed by the Birmingham company's prizefighting engineer Isaac Perrins.[5]

James McConnel, served an apprenticeship with William Cannan in Chowbent, and moved to Manchester in 1788 to work for Alexander Egelsom a weft and twist dealer with a cotton spinning establishment on Newton Street, Ancoats.The Murrays probably used the same building. In 1791 he joined the partnership with Sandford and Kennedy. By 1797 McConnel and Kennedy built their mill with steam powered spinning mules. This was Old Mill, and it was powered by a 16 hp Boulton and Watt in an external engine and boiler house. The mill had a cupola on the roof. It had 7 storeys and was 16 bays long by 4 bays deep.[6]

The next development came between 1801 and 1803. Long Mill was eight storeys high, 30 bays by 4 bays, the 45 hp Boulton and Watt was placed in a internal engine house to the south of the mill. The boilers were external. A tunnel and a bridge connected it with Old Mill. The Green Dragon public house on the corner of the plot, was left untouched. In 1809, a gas making plant was added to the site, and this became one of the first gas-lit mills. There were six gasometers. 1500 burners fed by a 19mm pipe.[7]

Colonel Sedgewick sold adjacent land to McConnel & Kennedy in 1817. The land was cleared, and the four blocks of the Sedgewick Mill were erected between 1818 and 1820. The largest, facing Redhill Street (Union Street), was 8 storeys by 17 bays. They were of fireproof construction, the main drive shaft ran in a tunnel beneath the ground floor from the internal engine house containing a 54 hp Boulton and Watt. This beam engine had a 24 feet (7.3 m) flywheel. Sir William Fairbairn and James Lillie, designed and installed the shafting, which was unusual as the wings of the mill were offset at 15 degrees to the right angle. The main shaft powered a vertical shaft in each bay that ran to each floor, and there to a shaft. This now was the largest employer in Manchester. John Kennedy retired in 1826, and the firm traded under the name of McConnel & McConnel Co.[8]

Alexis de Tocqueville, described Redhill Street Mill in 1835 as "... a place where some 1500 workers, labouring 69 hours a week, with an average wage of 11 shillings, and where three-quarters of the workers are women and children". During the Cotton Famine, the company had obtained rights to Heilmann's combing machine. As the century progressed, bigger and bigger machinery was used. Fairbairn and Lillie were employed to modify the structure of each of these mills in the mid 1860s. This involved replacing each of the old cast iron columns with new ones—each floor used a different technique.

Sedgewick New Mill, was an unusually narrow 5 storey L shaped mill, designed for doubling sewing thread by A. H. Stott. This was Stott's second commission and neither party were satisfied with the result.[9] McConnel became part of the Fine Spinners' and Doublers' Association Limited in 1898. The Paragon Mill and the New Old Mill were built in the Edwardian Baroque style by H. S. Porter using Accrington brick and terracotta. It had cast iron columns supporting by transverse steel beams and reinforced concrete floors. Initially they were built as 5 storey, though eventually 6 storey, 9 bay mills. The machines were electrically driven and a new substation was built in 1915. At the same time, Sedgewick New Mill and Long Mill were virtually rebuilt in order to take heavier equipment (usually this meant ring spinning frames).

Royal Visit

The mills were visited by King George VI and Queen Elizabeth in 1942. New Old Mill was renamed Royal Mill, it was extended, and cut Cotton Street with a new entrance arch claiming Royal Mill had been first built in 1797.[10]

Spinning ceases

Spinning ceased in 1959, and the frames were sold. The buildings were bought by Leslie Fink who let out the space. The Flatley Drying Company rented the Long Mill, but in February 1959 the mill burned down. It was redeveloped on 2001.[11]

References

- ^ Manchester 2000

- ^ Williams & Farnie 1992, p. 164

- ^ Miller & Wild 2007, pp. 21, 27

- ^ Miller & Wild 2007, p. 36

- ^ Musson, A. E.; Robinson, E. (June 1960). "The Origins of Engineering in Lancashire". The Journal of Economic History (Cambridge University Press on behalf of the Economic History Association) 20 (2): 224–225. JSTOR 2114855.

- ^ Miller & Wild 2007, p. 50

- ^ Miller & Wild 2007, p. 51

- ^ Miller & Wild 2007, p. 53

- ^ Miller & Wild 2007, p. 54

- ^ Miller & Wild 2007, p. 55

- ^ Miller & Wild 2007, p. 56

Bibliography

- Ashmore, Owen (1982). The Industrial Archaeology of North-west England. Manchester: Manchester University Press. ISBN 0-7190-0820-4.

- Williams, Mike; Farnie, D. A. (1992). Cotton Mills in Greater Manchester. Preston: Carnegie Publishing. ISBN 0-948789-89-1.

- Miller, Ian; Wild, Chris (2007), A & G Murray and the Cotton Mills of Ancoats, Lancaster: Oxford Archaeology North, ISBN 978-0-904220-46-9

- "Cotton Mills in Manchester and Salford 1891". Graces Guides. http://www.gracesguide.co.uk/wiki/Cotton_Mills_in_Manchester_and_Salford_1891. Retrieved 2009-11-13.

External links

Lancashire cotton Architects

Engine makers Daniel Adamson · Ashton Frost · Ashworth & Parker · Bateman & Sherratt · Boulton & Watt · Browett & Lindley · Buckley & Taylor · Carel · Earnshaw & Holt · Goodfellow · Fairbairn · W & J Galloway & Sons · B Goodfellow · Hick, Hargreaves & Co · Benjamin Hick and Sons · John Musgrave & Sons · J & W McNaught · Petrie of Rochdale · George Saxon · Scott & Hodgson · Urmson & Thompson · Yates of Blackburn · Yates & Thom · Whilans · J & E Wood · Woolstenhulmes & RyeMachinery makers Brooks & Doxey · Butterworth & Dickinson · Curtis, Parr & Walton · Dobson & Barlow · John Hetherington & Sons · Joseph Hibbert · Howard & Bullough · Geo. Hattersley · Asa Lees · Mather & Platt · Parr, Curtis & Madely · Platt Brothers · Taylor, Lang & Co · Textile Machinery Makers Ltd · Tweedales & Smalley- Oldham Limiteds · Fine Spinners and Doublers · Lancashire Cotton Corporation · Courtaulds · Bagley & WrightIndustrial processes Textile manufacturing · Cotton-spinning machinery · Friction Spinning · Magnetic ring spinning · Open end spinning · Ring spinning · Spinning frame · Spinning jenny · Spinning mule · Water frame · Roberts Loom · Lancashire LoomLists of mills LCC mills · Bolton · Bury · Cheshire · Derbyshire · Lancashire · Manchester · Oldham · Rochdale · Salford · Stockport · Tameside · WiganMuseums Categories:- Textile mills in Manchester

Wikimedia Foundation. 2010.