- Thermostat

-

This article is about the temperature regulating device. For the French cooking oven temperature scale, see Gas Mark#Other cooking temperature scales.

Honeywell's iconic "The Round" model T87 thermostat, one of which is in the Smithsonian.

Honeywell's iconic "The Round" model T87 thermostat, one of which is in the Smithsonian.

A Honeywell electronic thermostat in a retail store

A Honeywell electronic thermostat in a retail store

A thermostat is the component of a control system which regulates the temperature of a system so that the system's temperature is maintained near a desired setpoint temperature. The thermostat does this by switching heating or cooling devices on or off, or regulating the flow of a heat transfer fluid as needed, to maintain the correct temperature. The name is derived from the Greek words thermos "hot" and statos "a standing".

A thermostat may be a control unit for a heating or cooling system or a component part of a heater or air conditioner. Thermostats can be constructed in many ways and may use a variety of sensors to measure the temperature. The output of the sensor then controls the heating or cooling apparatus.

The first electric room thermostat was invented in 1883 by Warren S. Johnson.[1][2] Early technologies included mercury thermometers with electrodes inserted directly through the glass, so that when a certain (fixed) temperature was reached the contacts would be closed by the mercury. These were accurate to within a degree of temperature.

Common sensor technologies in use today include:

- Bimetallic mechanical or electrical sensors

- Expanding wax pellets

- Electronic thermistors and semiconductor devices

- Electrical thermocouples

These may then control the heating or cooling apparatus using:

- Direct mechanical control

- Electrical signals

- Pneumatic signals

Contents

Mechanical

This covers only devices which both sense and control using purely mechanical means.

Bimetal

Domestic water and steam based central heating systems have traditionally been controlled by bi-metallic strip thermostats, and this is dealt with later in this article. Purely mechanical control has been localised steam or hot-water radiator bi-metallic thermostats which regulated the individual flow. However, Thermostatic Radiator Valves (TRV) are now being widely used.

Purely mechanical thermostats are used to regulate dampers in some rooftop turbine vents, reducing building heat loss in cool or cold periods.

Some automobile passenger heating systems have a thermostatically controlled valve to regulate the water flow and temperature to an adjustable level. In older vehicles the thermostat controls the application of engine vacuum to actuators that control water valves and flappers to direct the flow of air. In modern vehicles, the vacuum actuators may be operated by small solenoids under the control of a central computer.

Wax pellet

Automotive

Main article: Wax thermostatic elementPerhaps the best example of purely mechanical technology in widespread use today is the internal combustion engine cooling thermostat. These are used to maintain the temperature of the engine near its optimum operating temperature by regulating the flow of coolant to an air cooled radiator. This type of thermostat operates purely mechanically, using a sealed chamber containing a wax pellet that melts and expands at a set temperature. The expansion of a sealed chamber operates a rod which opens a valve when the operating temperature is exceeded. The operating temperature is fixed, but is determined by the specific composition of the wax. Once the optimum operating temperature is reached, the thermostat progressively increases or decreases its opening in response to temperature changes, dynamically balancing the coolant recirculation flow and coolant flow to the radiator to maintain the engine temperature in the optimum range.

Shower and other hot water controls

A thermostatic mixing valve uses a wax pellet to control the mixing of hot and cold water. This provide protection from scalding, and convienient regulation of temperature for showers and baths.

Gas expansion

Thermostats are sometimes used to regulate gas ovens. It consists of a gas-filled bulb connected to the control unit by a slender copper tube. The bulb is normally located at the top of the oven. The tube ends in a chamber sealed by a diaphragm. As the thermostat heats up, the gas expands applying pressure to the diaphragm which reduces the flow of gas to the burner.

Pneumatic

A pneumatic thermostat is a thermostat that controls a heating and/or cooling system via a series of air-filled control tubes. This "control air" system responds to the pressure changes (due to temperature) in the control tube to activate heating or cooling when required. The control air typically is maintained on "mains" at 15-18psi (although usually operable up to 20psi). Pneumatic thermostats typically provide output/ branch/ post-restrictor(for single-pipe operation) pressures of 3-15psi which is piped to the end device (valve/ damper actuator/ Pneumatic-Electric switch, etc.)[3]

Electrical

Bimetallic switching thermostats

Water and steam based central heating systems have traditionally had overall control by wall-mounted bi-metallic strip thermostats. These sense the air temperature using the differential expansion of two metals to actuate an on/off switch. Typically the central system would be switched on when the temperature drops below the set point on the thermostat, and switched off when it rises above, with a few degrees of hysteresis to prevent excessive switching. Bi-metallic sensing is now being superseded by electronic sensors. A principal use of the bi-metallic thermostat today is in individual electric convection heaters, where control is on/off, based on the local air temperature and the set point desired by the user. These are also used on air-conditioners, where local control is required.

Simple two wire thermostats

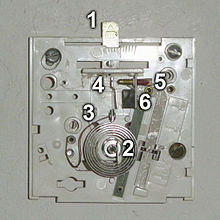

The illustration is the interior of a common two wire heat-only household thermostat, used to regulate a gas-fired heater via an electric gas valve. Similar mechanisms may also be used to control oil furnaces, boilers, boiler zone valves, electric attic fans, electric furnaces, electric baseboard heaters, and household appliances such as refrigerators, coffee pots, and hair dryers. The power through the thermostat is provided by the heating device and may range from millivolts to 240 volts in common North American construction, and is used to control the heating system either directly (electric baseboard heaters and some electric furnaces) or indirectly (all gas, oil and forced hot water systems). Due to the variety of possible voltages and currents available at the thermostat, caution must be taken when selecting a replacement device.

- Set point control lever. This is moved to the right for a higher temperature. The round indicator pin in the center of the second slot shows through a numbered slot in the outer case.

- Bimetallic strip wound into a coil. The center of the coil is attached to a rotating post attached to lever (1). As the coil gets colder the moving end — carrying (4) — moves clockwise.

- Flexible wire. The left side is connected via one wire of a pair to the heater control valve.

- Moving contact attached to the bimetal coil.thence to the heater's controller.

- Magnet. This ensures a good contact when the contact closes. It also provides hysteresis to prevent short heating cycles, as the temperature must be raised several degrees before the contacts will open. As an alternative, some thermostats instead use a mercury switch on the end of the bimetal coil. The weight of the mercury on the end of the coil tends to keep it there, also preventing short heating cycles. However, this type of thermostat is banned in many countries due to its highly and permanently toxic nature if broken. When replacing these thermostats they must be regarded as chemical waste.

- Fixed contact screw. This is adjusted by the manufacturer. It is connected electrically by a second wire of the pair to the thermocouple and the heater's electrically operated gas valve.

Not shown in the illustration is a separate bimetal thermometer on the outer case to show the actual temperature at the thermostat.

Millivolt thermostats

As illustrated in the use of the thermostat above, the power is provided by a thermocouple, heated by the pilot light. This produces little power and so the system must use a low power valve to control the gas. This type of device is generally considered obsolete as pilot lights waste a surprising amount of gas (in the same way a dripping faucet can waste a large amount of water over an extended period), and are also no longer used on stoves, but are still to be found in many gas water heaters and gas fireplaces. (Their poor efficiency is acceptable in water heaters, since most of the energy "wasted" on the pilot light is still being coupled to the water and therefore helping to keep the tank warm). It also makes it unnecessary for an electrical circuit to be run to the water heater. For tankless (on demand) water heaters, pilot ignition is preferable because it is faster than hot-surface ignition and more reliable than spark ignition.)

Some programmable thermostats will control these systems.

24 volt thermostats

The majority of modern heating/cooling/heat pump thermostats operate on low voltage (typically 24 volts AC) control circuits. The source of the 24 volt AC power is a control transformer installed as part of the heating/cooling equipment. The advantage of the low voltage control system is the ability to operate multiple electromechanical switching devices such as relays, contactors, and sequencers using inherently safe voltage and current levels.[4] Built into the thermostat is a provision for enhanced temperature control using anticipation. A heat anticipator generates a small amount of additional heat to the sensing element while the heating appliance is operating. This opens the heating contacts slightly early to prevent the space temperature from greatly overshooting the thermostat setting. A mechanical heat anticipator is generally adjustable and should be set to the current flowing in the heating control circuit when the system is operating. A cooling anticipator generates a small amount of additional heat to the sensing element while the cooling appliance is not operating. This causes the contacts to energize the cooling equipment slightly early, preventing the space temperature from climbing excessively. Cooling anticipators are generally non-adjustable.

Electromechanical thermostats use resistance elements as anticipators. Most electronic thermostats use either thermistor devices or integrated logic elements for the anticipation function. In some electronic thermostats, the thermistor anticipator may be located outdoors, providing a variable anticipation depending on the outdoor temperature. Thermostat enhancements include outdoor temperature display, programmability, and system fault indication. While such 24 volt thermostats are incapable of operating a furnace when the mains power fails, most such furnaces require mains power for heated air fans (and often also hot-surface or electronic spark ignition) so no functionality is lost. In other circumstances such as piloted wall and "gravity" (fanless) floor and central heaters the low voltage system described previously may be capable of remaining functional when electrical power is unavailable.Ignition sequences in modern systems

- Gas

-

- Start drafting fan (if the furnace is relatively recent) to create a column of air flowing up the chimney

- Heat ignitor or start spark-ignition system

- Open gas valve to ignite main burners

- Wait (if furnace is relatively recent) until the heat exchanger is at proper operating temperature before starting main blower fan or circulator pump

- Oil

-

- Similar to gas, except rather than opening a valve, the furnace will start an oil pump to inject oil into the burner

- Electric

-

- The blower fan or circulator pump will be started, and a large electromechanical relay or TRIAC will turn on the heating elements

- Coal (including grains such as corn, wheat, and barley, or pellets made of wood, bark, or cardboard)

-

- Generally rare today (though grains and pellets are increasing in popularity); similar to gas, except rather than opening a valve, the furnace will start a screw to drive coal/grain/pellets into the firebox

With non-zoned (typical residential, one thermostat for the whole house) systems, when the thermostat's R (or Rh) and W terminals are connected, the furnace will go through its startup rituals and produce heat.

With zoned systems (some residential, many commercial systems — several thermostats controlling different "zones" in the building), the thermostat will cause small electric motors to open valves or dampers and start the furnace or boiler if it's not already running.

Most programmable thermostats will control these systems.

Line voltage thermostats

Line voltage thermostats are most commonly used for electric space heaters such as a baseboard heater or a direct-wired electric furnace. If a line voltage thermostat is used, system power (in the United States, 120 or 240 volts) is directly switched by the thermostat. With switching current often exceeding 40 amperes, using a low voltage thermostat on a line voltage circuit will result at least in the failure of the thermostat and possibly a fire. Line voltage thermostats are sometimes used in other applications, such as the control of fan-coil (fan powered from line voltage blowing through a coil of tubing which is either heated or cooled by a larger system) units in large systems using centralized boilers and chillers, or to control circulation pumps in hydronic heating applications.

Some programmable thermostats are available to control line-voltage systems. Baseboard heaters will especially benefit from a programmable thermostat which is capable of continuous control (as are at least some Honeywell models), effectively controlling the heater like a lamp dimmer, and gradually increasing and decreasing heating to ensure an extremely constant room temperature (continuous control rather than relying on the averaging effects of hysteresis). Systems which include a fan (electric furnaces, wall heaters, etc.) must typically use simple on/off controls.

Combination heating/cooling regulation

Depending on what is being controlled, a forced-air air conditioning thermostat generally has an external switch for heat/off/cool, and another on/auto to turn the blower fan on constantly or only when heating and cooling are running. Four wires come to the centrally-located thermostat from the main heating/cooling unit (usually located in a closet, basement, or occasionally in the attic): One wire supplies a 24 volts AC power connection to the thermostat, while the other three supply control signals from the thermostat, one for heat, one for cooling, and one to turn on the blower fan. The power is supplied by a transformer, and when the thermostat makes contact between power and another wire, a relay back at the heating/cooling unit activates the corresponding function of the unit.

A thermostat, when set to "cool", will only turn on when the ambient temperature of the surrounding room is above the set temperature. Thus, if the controlled space has a temperature normally above the desired setting when the heating/cooling system is off, it would be wise to keep the thermostat set to "cool", despite what the temperature is outside. On the other hand, if the temperature of the controlled area falls below the desired degree, then it is advisable to turn the thermostat to "heat".

Heat pump regulation

The heat pump is a refrigeration based appliance which reverses refrigerant flow between the indoor and outdoor coils. This is done by energizing a reversing valve (also known as a "4-way" or "change-over" valve). During cooling, the indoor coil is an evaporator removing heat from the indoor air and transferring it to the outdoor coil where it is rejected to the outdoor air. During heating, the outdoor coil becomes the evaporator and heat is removed from the outdoor air and transferred to the indoor air through the indoor coil. The reversing valve, controlled by the thermostat, causes the change-over from heat to cool. Residential heat pump thermostats generally have an "O" terminal to energize the reversing valve in cooling. Some residential and many commercial heat pump thermostats use a "B" terminal to energize the reversing valve in heating. The heating capacity of a heat pump decreases as outdoor temperatures fall. At some outdoor temperature (called the balance point) the ability of the refrigeration system to transfer heat into the building falls below the heating needs of the building. A typical heat pump is fitted with electric heating elements to supplement the refrigeration heat when the outdoor temperature is below this balance point. Operation of the supplemental heat is controlled by a second stage heating contact in the heat pump thermostat. During heating, the outdoor coil is operating at a temperature below the outdoor temperature and condensation on the coil may take place. This condensation may then freeze onto the coil, reducing its heat transfer capacity. Heat pumps therefore have a provision for occasional defrost of the outdoor coil. This is done by reversing the cycle to the cooling mode, shutting off the outdoor fan, and energizing the electric heating elements. The electric heat in defrost mode is needed to keep the system from blowing cold air inside the building. The elements are then used in the "reheat" function. Although the thermostat may indicate the system is in defrost and electric heat is activated, the defrost function is not controlled by the thermostat. Since the heat pump has electric heat elements for supplemental and reheats, the heat pump thermostat provides for use of the electric heat elements should the refrigeration system fail. This function is normally activated by an "E" terminal on the thermostat. When in emergency heat, the thermostat makes no attempt to operate the compressor or outdoor fan.

Digital

See also: Programmable thermostatNewer digital thermostats have no moving parts to measure temperature and instead rely on thermistors or other semiconductor devices such as a resistance thermometer (resistance temperature detector). Typically one or more regular batteries must be installed to operate it, although some so-called "power stealing" digital thermostats use the common 24 volt AC circuits as a power source, but will not operate on thermopile powered "millivolt" circuits used in some furnaces. Each has an LCD screen showing the current temperature, and the current setting. Most also have a clock, and time-of-day and even day-of-week settings for the temperature, used for comfort and energy conservation. Some advanced models have touch screens, or the ability to work with home automation or building automation systems.

Digital thermostats use either a relay or a semiconductor device such as triac to act as switch to control the HVAC unit. Units with relays will operate millivolt systems, but often make an audible "click" noise when switching on or off.

More expensive models have a built-in PID controller, so that the thermostat knows ahead how the system will react to its commands. For instance, setting it up that temperature in the morning at 7 a.m. should be 21°C, makes sure that at that time the temperature will be 21°C, where a conventional thermostat would just start working at that time. The PID controller decides at what time the system should be activated in order to reach the desired temperature at the desired time. It also makes sure that the temperature is very stable (for instance, by reducing overshoots[citation needed]).

Most digital thermostats in common residential use in North America and Europe are programmable thermostats, which will typically provide a 30% energy savings if left with their default programs; adjustments to these defaults may increase or reduce energy savings.[citation needed] The programmable thermostat article provides basic information on the operation, selection and installation of such a thermostat.

Household thermostat location

The thermostat should be located away from the room's cooling or heating vents or device, yet exposed to general airflow from the room(s) to be regulated. An open hallway may be most appropriate for a single zone system, where living rooms and bedrooms are operated as a single zone. If the hallway may be closed by doors from the regulated spaces then these should be left open when the system is in use. If the thermostat is too close to the source controlled then the system will tend to "short cycle", and numerous starts and stops can be annoying and in some cases shorten equipment life. A multiple zoned system can save considerable energy by regulating individual spaces, allowing unused rooms to vary in temperature by turning off the heating and cooling.

Dummy thermostats

It has been reported that many thermostats in office buildings are non-functional dummy devices, installed to give tenants' employees an illusion of control.[5][6] These dummy thermostats are in effect a type of placebo button. However, these thermostats are often fully functional in the sense that they are used to detect the temperature in the zone, even though their controls are disabled and not used in lieu of the environmental controls of the building. This function is often referred to as "lockout".[7]

See also

- Automatic control

- On-off control

- OpenTherm

References

- ^ "Thermostat Maker Deploys Climate Control Against Climate Change". America.gov. http://www.america.gov/st/business-english/2008/July/20080710104405saikceinawz0.5803339.html. Retrieved 2009-10-03.

- ^ "Johnson Controls Inc. | History". Johnsoncontrols.com. 2007-11-07. http://www.johnsoncontrols.com/publish/us/en/about/our_history.html. Retrieved 2009-10-03.

- ^ http://www.dr-fix-it.com/pneum1.html

- ^ Electrical potentials at and below 24 volts are classed as "Safety Extra-Low Voltage" under most electrical codes when supplied through an isolation transformer.

- ^ Sandberg, Jared (15 Jan 2003). "Employees Only Think They Control Thermostat". The Wall Street Journal. http://online.wsj.com/article/SB1042577628591401304.html. Retrieved 2009-09-02.

- ^ Katrina C. Arabe (April 11, 2003). ""Dummy" Thermostats Cool Down Tempers, Not Temperatures". http://news.thomasnet.com/IMT/archives/2003/04/dummy_thermosta.html. Retrieved 2010-02-13.

- ^ Example datasheet of current art thermostat, exhibiting lockout functionality : http://cgproducts.johnsoncontrols.com/MET_PDF/12011079.pdf

External links

- Professional Reference Guide

- "How A Thermostat Tends Your Furnance" 1951 article on the basics of the automatic furnace thermostats—this reference has good drawings and illustrations.

Electronic components Semiconductors Avalanche diode • Barretter • Darlington transistor • DIAC • Diode • Field-effect transistor (FET) • Insulated-gate bipolar transistor (IGBT) • JFET • Light-emitting diode (LED) • Memristor • MOSFET • Photodetector • PIN diode • Silicon-controlled rectifier (SCR) • Thyristor • Transistor • TRIAC • Unijunction transistor (UJT) • Zener diodeVacuum tubes Vacuum tubes (RF) Backward wave oscillator (BWO) • Cavity magnetron • Crossed-field amplifier • Gyrotron • Inductive output tube (IOT) • Klystron • Maser • Traveling-wave tubeAdjustable Passive Connector (Electrical power, Baseband, RF) • Ferrite • Fuse • Resettable fuse • Resistor (Thermistor) • TransformerReactive Categories:- Switches

- Temperature control

Wikimedia Foundation. 2010.