- Demand chain management

-

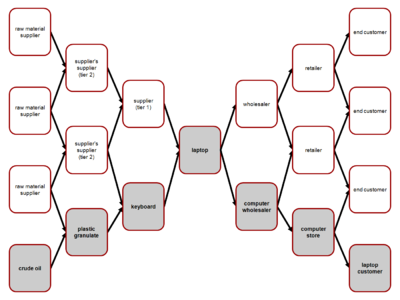

Demand chain management is aimed at managing complex and dynamic supply and demand networks.[1] (cf. Wieland/Wallenburg, 2011)

Demand chain management is aimed at managing complex and dynamic supply and demand networks.[1] (cf. Wieland/Wallenburg, 2011)

Demand chain management is the management of upstream and downstream relationships between suppliers and customers to deliver the best value to the customer at the least cost to the demand chain as a whole. The term demand chain management is used to denote the concept commonly referred to as supply chain management, however with special regard to the customer pull.[2] In that sense, demand chain management software tools bridge the gap between the customer relationship management and the supply chain management.[3] The organization’s supply chain processes are managed to deliver best value according to the demand of the customers. A study of the university in Wageningen (the Netherlands) sees DCM as an extension of supply chain management, due to its incorporation of the market orientation perspective on its concept.[4] While the term "demand-driven supply chain or network" denotes a set of concepts, the term "demand-driven execution" or DDE is used to express the means of achieving those concepts.[citation needed]

Contents

Demand-driven supply network

A Demand-driven supply network (DDSN) is one method of supply chain management which involves building supply chains in response to demand signals. The main force of DDSN is that it is driven by customers demand. In comparison with the traditional supply chain, DDSN uses the pull technique. It gives DDSN market opportunities to share more information and to collaborate with others in the supply chain.

DDSN uses a capability model that consist of four levels. The first level is Reacting, the second level is Anticipating, the third level is Collaborating and the last level is Orchestrating. The first two levels focus on the internal supply chain while the last two levels concentrate on external relations throughout the Extended Enterprise.[5]

Competitive advantages

To create sustainable competitive advantages with DDSN, companies have to do deal with three conditions: Alignment (create shared incentives), Agility (respond quickly to short-term change) and Adaptability (adjust design of the supply chain).[6]

Misconceptions

There are five commonly made misconceptions of demand driven (DDSN):.[7]

- Companies might think they are demand driven because they have a good forecast of their company.

- They have implemented lean manufacturing.

- They have great data on all their customers.

- They think it is a technology project and the corporate forecast is a demand visibility signal.

- They have a better view of customers demand.

An important component of DDSN is DDM (“real-time” demand driven manufacturing). DDM gives customers the opportunity to say what they want, where and when.

Demand-driven Execution

Demand chain management is the same as supply chain management, but with emphasis on consumer pull vs. supplier push.[2] The demand chain begins with customers, then funnels through any resellers, distributors, and other business partners who help sell the company’s products and services. The demand chain includes both direct and indirect sales forces.[8] Customers demand is hard to detect because out of stock situations (OOS) falsify data collected from POS-Terminals. According to studies of Corsten/Gruen (2002, 2008)[9] the OOS-rate is about 8%. For products under sales promotion OOS rates up to 30% exist. Reliable information about demand is necessary for DCM therefore lowering OOS is a main factor for successful DCM.

Corsten and Gruen describe key factors for lowering OOS-rates:

- data accuracy

- forecast and order accuracy

- order quantity

- replenishment

- Capacity (time supply)

- Capacity (Packout) and Planogram Compliance

- Shelf Replenishment

Implementation of system supported processes leads to the new technology Extreme Transaction Processing described by Gartner Research.[10] This technology allows to process the huge amount of data (POS, RFID) in real time providing information for store managers, shelve managers and the supply chain.

See also

References

- ^ cf. Andreas Wieland, Carl Marcus Wallenburg (2011): Supply-Chain-Management in stürmischen Zeiten. Berlin.

- ^ a b Business forecasting, Demand planning, Inventory planning, Sales and operations planning, Sales forecasting software and services

- ^ QUANTOS SaRL - Demand Chain Management Solutions Take Hold With Selling Organizings, According To New Aberdeen Report

- ^ Abstract WU dissertation no. 4036

- ^ Martin R, 2006, GMA and AMR Research, The Demand Driven Supply Network DDSN, Your Business Operating Strategy; 15

- ^ Lee, H, 2004. The Triple –A Supply Chain. Harvard Business Review 82; 10 102-112

- ^ Cecere, L., Hofman, D., Martin, R., Preslan L., The Handbook for Becoming Demand Driven, AMR Research, Juli 2005; 4

- ^ Beyond CRM: The Critical Path to Successful Demand Chain Management www.crmadvocate.com/required/scribe1.pdf

- ^ Retail out of Stocks

- ^ Gartner Research Magic Quadrant for Enterprise Application Servers 2Q08

Further reading

Categories:- Commercial item transport and distribution

- Supply chain management

- Management

- Distribution, retailing, and wholesaling

Wikimedia Foundation. 2010.