- Ready-mix concrete

-

The inside of a transit mixer uses a simple Archimedes' screw to mix and to lift the concrete to the delivery chute.

The inside of a transit mixer uses a simple Archimedes' screw to mix and to lift the concrete to the delivery chute.

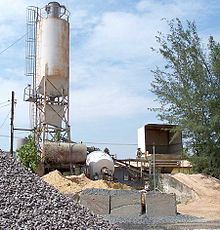

Ready-mix concrete is a type of concrete that is manufactured in a factory or batching plant, according to a set recipe, and then delivered to a work site, by truck mounted transit mixers . This results in a precise mixture, allowing specialty concrete mixtures to be developed and implemented on construction sites. The first ready-mix factory was built in the 1930s, but the industry did not begin to expand significantly until the 1960s, and it has continued to grow since then.

Ready-mix concrete is sometimes preferred over on-site concrete mixing because of the precision of the mixture and reduced work site confusion. However, using a pre-determined concrete mixture reduces flexibility, both in the supply chain and in the actual components of the concrete.

The leading ready-mix concrete supplier worldwide is the Mexican concrete company Cemex; its main competitor is France-based Lafarge and the leading ready-mix concrete supplier in Middle East is the Unibeton Ready Mix.

Ready Mixed Concrete is also referred as the customized concrete products for commercial purpose. the Ready-mix Concrete Company offer different concrete according to user's mix design or industrial standard.

The Ready mixed concrete company is required to equip themselves with up-to-date equipments, such as transit mixer, concrete pump, and Concrete Batching Plant, which needs visualized production management software and also PLC controller.

Ready Mixed Concrete, or RMC as it is popularly called, refers to concrete that is specifically manufactured for delivery to the customer's construction site in a freshly mixed and plastic or unhardened state. Concrete itself is a mixture of Portland cement, water and aggregates comprising sand and gravel or crushed stone. In traditional work sites, each of these materials is procured separately and mixed in specified proportions at site to make concrete. Ready Mixed Concrete is bought and sold by volume - usually expressed in cubic meters. RMC can be custom-made to suit different applications.

Ready Mixed Concrete is manufactured under computer-controlled operations and transported and placed at site using sophisticated equipment and methods. RMC assures its customers numerous benefits.

Advantages of Ready mix Concrete over Site mix Concrete

- A centralised concrete batching plant can serve a wide area.

- The plants are located in areas zoned for industrial use, and yet the delivery trucks can service residential districts or inner cities.

- Better quality concrete is produced.

- Elimination of storage space for basic materials at site.

- Elimination of procurement / hiring of plant and machinery

- Wastage of basic materials is avoided.

- Labor associated with production of concrete is eliminated.

- Time required is greatly reduced.

- Noise and dust pollution at site is reduced.

- Reduce cost.

Disadvantages of Ready-Mix Concrete

- The materials are batched at a central plant, and the mixing begins at that plant, so the traveling time from the plant to the site is critical over longer distances. Some sites are just too far away, though this is usually a commercial rather than technical issue.

- Generation of additional road traffic; furthermore, access roads, and site access have to be able to carry the weight of the truck and load. Concrete is approx. 2.5tonne per m³. This problem can be overcome by utilizing so-called 'minimix' companies, using smaller 4m³ capacity mixers able to access more restricted sites.

- Concrete's limited timespan between mixing and going-off means that readymix should be placed within 120 minutes of batching at the plant. Modern additives modify precisely that timespan however, the amount of additive added to the mix is very important.

Categories:- Concrete

- Building materials

Wikimedia Foundation. 2010.